STOP! Don't Use That Oil Unless It Says TRP or Tektro

TRP/ Tektro mineral oil is specifically designed for:

- High heat environments (>200℃ boiling point)

- Resisting oxidation and breakdown over time

- Consistent viscosity across a wide range of temperatures

- Compatibility with seals and internal components within TRP and Tektro brakes

This means smooth lever feel, consistent bite point, and long-term reliability—even after months of hard riding.

The Wrong Oil Can Wreck Your Brakes

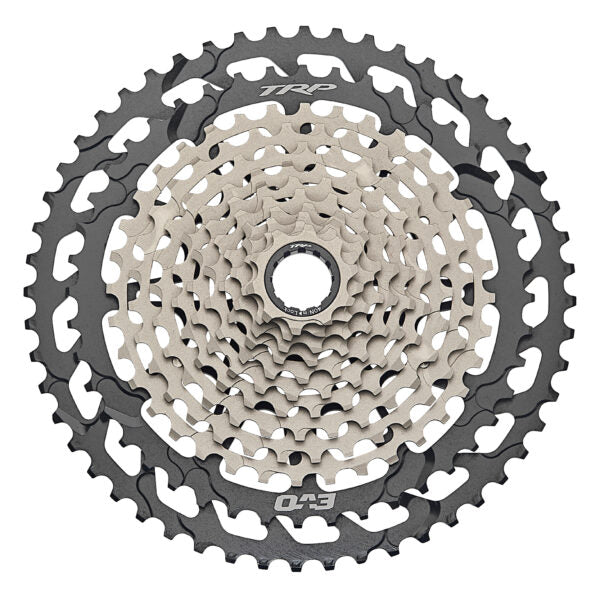

“Above: used Shimano oil flushed from a DH-R EVO”

Using other mineral oils, including Shimano’s, can lead to premature fluid breakdown, seal degradation, and even internal contamination in TRP brakes.

For example:

- Shimano mineral oil has been shown to burn and carbonize inside TRP systems, turning black within a short period—even with light use.

- This leads to inconsistent lever feel, decreased power, and the need for more frequent bleeds or even full rebuilds.

In contrast, TRP/Tektro oil remains stable—even after 6 months of frequent use, it still retains its red hue and performance properties.

Designed to Work as a System

Every component in your TRP or Tektro brake system is optimized to work with our fluid—swapping it for another brand's mineral oil introduces variables we can’t predict, and results we can’t guarantee.

To keep your brakes performing at their peak, always use TRP or Tektro mineral oil. It’s not just fluid—it’s a critical part of the system.

Safe Handling Guidelines for TRP Mineral Oil

Like any chemical product, TRP Mineral Oil requires careful handling to ensure safety during use and maintenance.

Basic Handling Practices

- Always tightly close containers after dispensing oil to prevent contamination or evaporation.

- Do not eat, drink, smoke, or inhale vapors while working with mineral oil.

- Wash hands thoroughly before breaks and after handling the product.

Protective Measures

- Eye Protection: Wear safety glasses as a minimum. If there’s a risk of splashing, chemical-resistant goggles compliant with DIN EN 166 are recommended.

- Skin Protection: If your work involves prolonged or repeated contact with mineral oil, wear suitable chemical-resistant gloves to avoid irritation or absorption through the skin.

Have questions about brake fluid, bleeding, or service intervals? Reach out to our tech team or check out our service guides to make sure your brakes stay dialed.

Taking the right precautions helps protect you—and ensures your brake system maintenance is done safely and effectively.